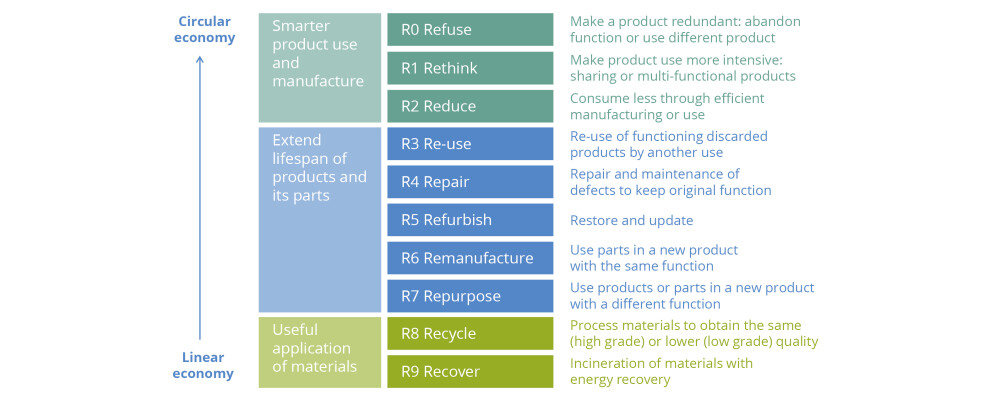

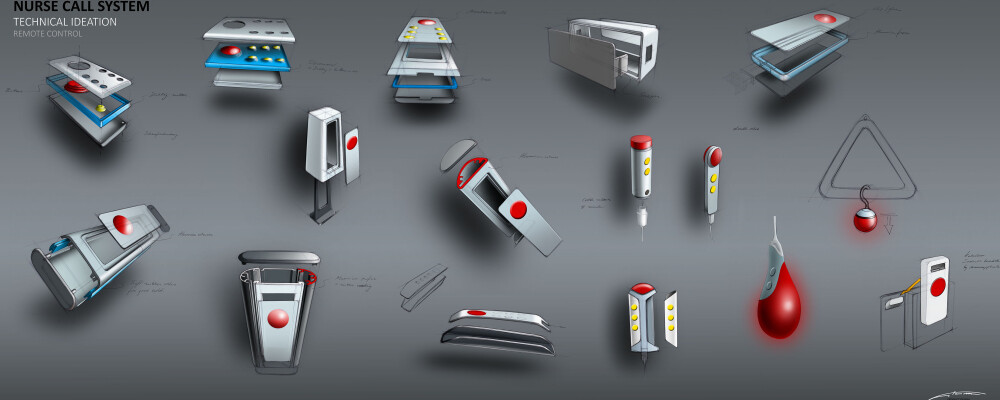

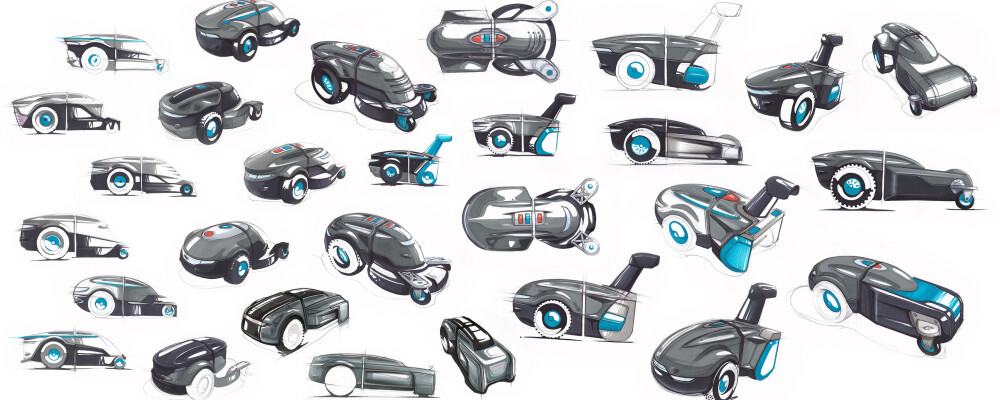

The process

Every project, every product requires a specific design process to achieve the best possible result with the available budget. Therefore a custom made process will be proposed and fine-tuned together with the client at the beginning of a cooperation.